Table of Contents

Why Repair Your Parking Lot

Commercial Risk And Cost Impact

Deferred concrete parking lot repair is a liability multiplier, not a cost-saving measure. Houston property owners watching trivial cracks morph into costly failures within a year have learned this lesson the hard way. Minor surface defects become potholes and broken slabs as thermal cycles, water intrusion, and relentless traffic accelerate deterioration. Facility managers at industrial sites in North Houston routinely pay up to 5x more for reconstruction when repairs are neglected. Damaged lots not only drive up long-term capital outlays, but also increase the risk of injury lawsuits, code violations, and damage to client reputation.

Silver Spur Role And Approach

Silver Spur Concrete stands alone in Houston as a single-source provider for end-to-end parking lot repair. Unlike fragmented subcontractor-driven models, Silver Spur self-performs every critical stage. Their design-build process applies nearly two decades of concrete mix and placement expertise, delivering results where most general contractors flounder. Property owners seeking reliable, accountable partners insist on Silver Spur for one reason: inferior repairs cost more every time. Clients in Tomball, Magnolia, and Conroe report expedited project schedules and fewer disruptions due to direct control over labor, equipment, and local material supply. This in-house approach means lower risk of coordination failures, tighter quality control, and the technical insights that prevent recurring problems in Houston’s unforgiving soil and climate.

What This Guide Covers

There is no room for guesswork with commercial parking lot repair in Houston. This guide tackles every factor impacting your facility’s ROI: types of concrete failures, climate-driven root causes, visual and structural warning signs, full repair process, and creative strategies that minimize downtime without sacrificing quality. You’ll see clear cost ranges and lifecycle value comparisons, fully transparent service timelines, warranty practices, and side-by-side evaluations against local competitors. For property managers and owners tired of endless repairs and opaque pricing, this guide ends the uncertainty.

Common Concrete Failures

Causes In Houston Climate

Houston’s climate and soils engineer concrete problems no contractor from out of state can truly anticipate. Salt intrusion from groundwater and humidity-driven expansion causes microcracks invisible to the untrained eye. Extreme temperature cycles–over 100°F in June, plunging near freezing in January–create repeated stress on rigid slabs. Heavy truck traffic from logistics, healthcare, and industrial users amplifies the effect, while North Houston sites near Navasota and Bryan deal with swelling clay soils that fracture poorly designed surfaces in months, not years. Tree root heave and patchwork drainage only accelerate failure. Builders familiar with Houston subgrade conditions know that rigorous prep, moisture barrier selection, and proper joint placement are non-negotiable.

Inspection And Assessment Signs

The five recurring structural red flags in Houston parking lots are: spalling (surface flaking), network cracking, joint failure, slab settlement, and classic pop-out patterns. Any first sign–a hairline crack, a puddle near a joint, a single trip hazard–should trigger a formal inspection. Neglect unleashes exponential damage, forcing a leap from simple patching to full-depth replacement. Crews from reputable contractors use surface hardness testing and core sampling, not visual guesswork, to diagnose root failures. Proactive facilities teams plan capital budgets around these indicators, avoiding last-minute emergencies.

Who To Call For Repairs

Generalists and subcontractors make promises; true commercial concrete repair demands experienced design-build partners. Silver Spur’s dedicated Commercial Concrete Repair and Concrete Parking Lot Contractors divisions deliver engineered solutions–not cheap patches–backed by local case studies ranging from churches to multi-acre industrial sites. Owners have learned that price shopping routine repairs from unvetted firms guarantees costly callbacks and interim fixes. Firms adept in Houston’s codes, soils, and climate will always outperform itinerant contractors or asphalt-focused crews dabbling in concrete.

Value Of Professional Repair

Cost Savings And Longevity

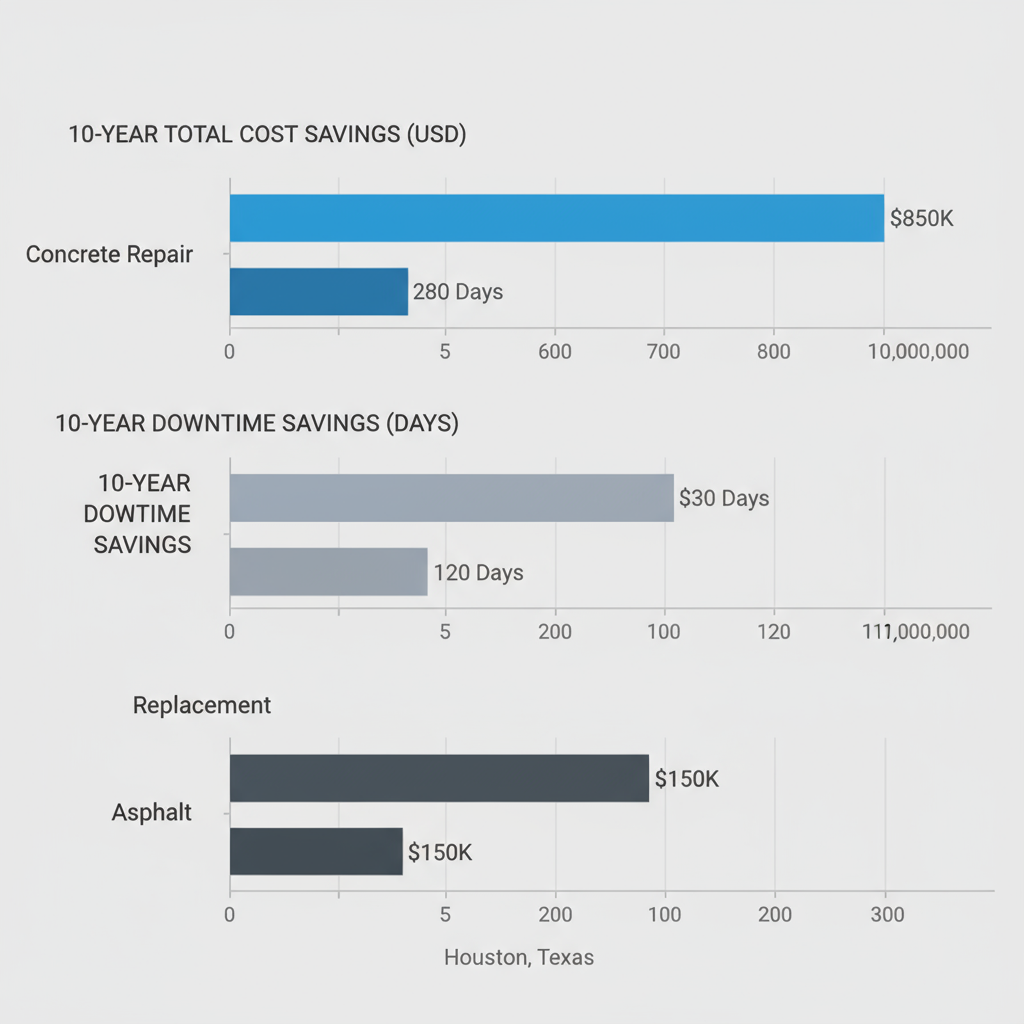

Professional repair is not a marginal improvement; it’s a quantifiable cost saver. Data shows that resurfacing with engineered overlays or in-situ slab repair cuts total expenditure over a 10-year span by 30-60% versus full replacement. A $40,000 repair, when paired with scheduled sealing, can avoid $120,000 in rebuild costs. Design-build repair uniquely extends pavement service life, proven in repeat projects for regional healthcare and education clients. Silver Spur’s clients report four to five years of zero-defect performance after professional repair compared to 18-24 months for interim patchwork from national franchise chains.

Comparing lifecycle costs and downtime of concrete repair versus other paving options.

Safety And Compliance

Compliance failures are among the most expensive mistakes Houston property owners make. ADA lawsuits routinely exceed $25,000 per incident, with non-conforming slopes and joint heights a primary source. Houston’s stormwater ordinances and site drainage codes demand expert evaluation, not quick fixes–misplaced drains are a leading cause of ongoing slab settlement. Proper repairs upgrade slip resistance and address standing water, directly reducing liability exposure. Silver Spur’s warranty-backed work ensures continual compliance, so facility managers avoid the never-ending cycle of re-inspection and emergency code correction.

Service Comparison Table

| Provider | Services Covered | Pricing Estimate | Typical Timeline |

|---|---|---|---|

| Silver Spur Concrete Contractors | Design-build concrete parking lot repair, resurfacing, joint repair, ADA upgrades, drainage correction, and ongoing maintenance. | Typical commercial repair projects range from $6,000 to $75,000 depending on scope; unit repairs or slab replacements priced per square foot. | Small repairs: 1-3 days. Moderate resurfacing: 3-10 days. Full slab replacement: 2-4 weeks depending on curing and phasing. |

| Local Competitor A | General concrete repair, selective resurfacing, contractor-managed subcontracted installs. | Ranges typically 10-20% higher than self-perform firms due to subcontracting and overhead; exact bids vary. | Similar small repair timelines but longer for complex work when coordinated with subcontractors, often 1-6 weeks. |

| Local Competitor B | Asphalt-focused, concrete patching, limited design-build, fewer warranty options. | Lower upfront cost on minor patches but higher lifecycle costs; variable pricing. | Quick patching: 1-2 days; larger projects require longer schedules. |

| Local Competitor C | Full-site reconstruction, multiple subcontractors and extended mobilization. | Higher capital expense for turnkey reconstruction; bids above market average. | Full reconstruction: 3-8 weeks including demolition, grading, pours, and cure times. |

Repair Process Explained

Initial Evaluation And Testing

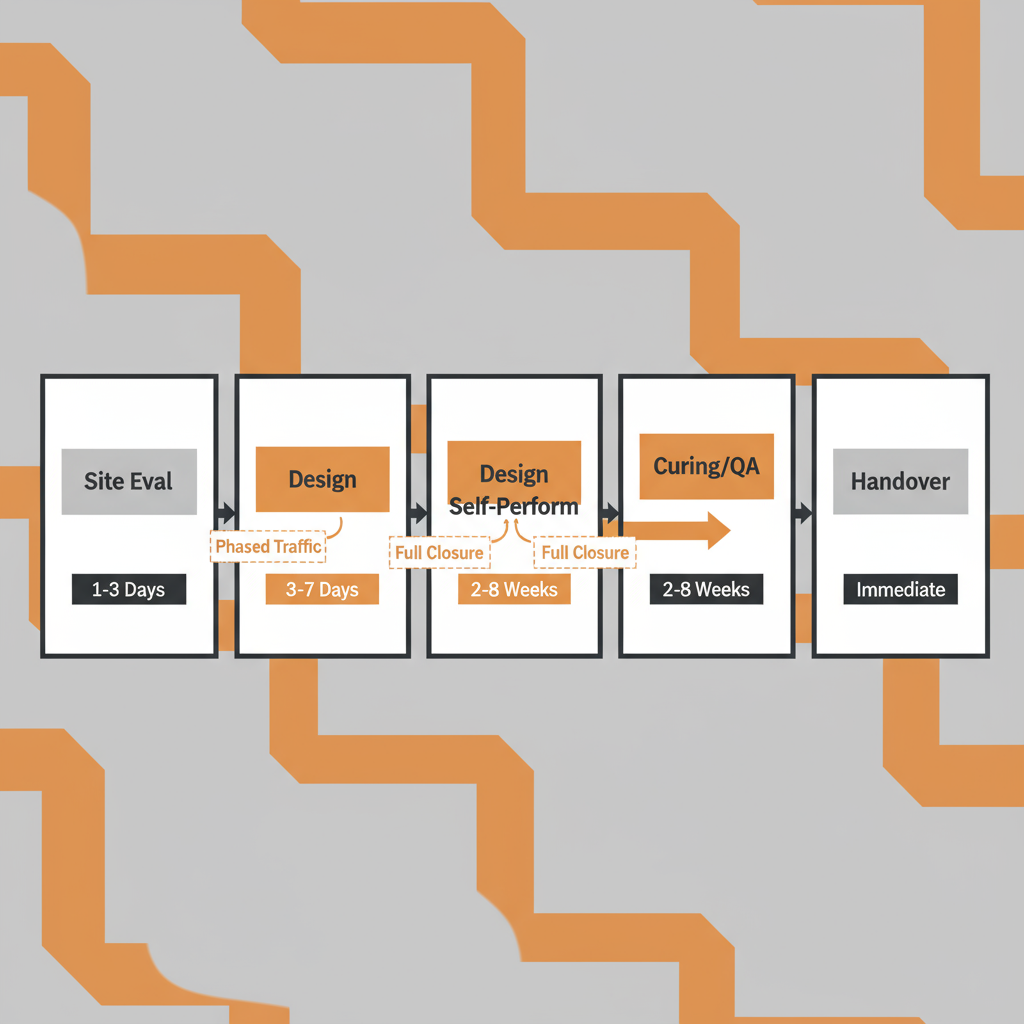

A concrete repair done right in Houston always begins with a systematic site evaluation. Silver Spur deploys trained crews for site surveys, not sales reps. Core sampling and non-destructive hardness testing determine the real failure modes, whether subgrade movement or surface wear. Drainage analysis pinpoints hidden causes–often missed by warranty-only contractors fixated on patching symptoms. Major failures trigger root cause studies; for example, a Conroe warehouse lost a third of its slab volume to poor compaction under high-frequency truck routes, diagnosed and remedied in Silver Spur’s initial assessment phase.

Common Repair Methods

Houston demands a tactical repair arsenal. Localized patching targets small breaks or spalls with custom high-strength mixes. Diamond grinding erases surface unevenness and extends ADA compliance. Partial slab replacement and full-depth reconstruction, guided by field testing, address underlying structural failures. Joint resealing–often skipped by budget crews–is essential here to prevent water infiltration, a notorious root issue in Houston. Upgrades to trench drains and surface water management protect from Houston’s routine flash floods.

Scheduling And Completion Time

The biggest misconception in Houston property management: concrete repairs must involve massive downtime. In practice, phased traffic controls and night/weekend work limit disruptions. Silver Spur routinely completes small repairs in 1-3 days, mid-sized resurfacing in 3-10 days, and full slab replacement in 2-4 weeks with phased access. Key timeline influencers include summer heat, humidity (affecting cure and strength gain), and material logistics. Commercial clients from healthcare to education have kept critical access open throughout repairs via facility-tailored phasing–despite forecasts predicting schedules would slip by weeks.

Silver Spur’s commercial concrete repair process, from evaluation to handover.

Maintenance And Best Practices

Proactive Maintenance Tactics

It’s industry malpractice to treat parking lot repair as a one-time task. Houston’s real leaders embrace scheduled maintenance: joint resealing every 3-5 years, surface cleaning to remove debris and block water intrusion, and targeted crack filling before minor issues become catastrophic. The smart money invests in annual drainage checks–missed only by owners who enjoy surprise emergency bills. The best outcomes come from partnering with contractors who document post-repair conditions and propose stepwise maintenance plans, not afterthoughts buried in a closing invoice.

Warranty And Lifecycle Planning

Only sound contractors are willing to document their work with robust warranties. Houston commercial projects typically carry 1-3 year labor and material coverage, with Silver Spur offering extended terms on design-build work–an industry rarity. Lifecycle cost comparisons show that owners using warranty-backed maintenance and scheduled inspections pay up to 45% less over 10 years. The combination of professional repair, documented warranties, and regular follow-up stands in stark contrast to the churn-and-burn approach dominating the bottom tier of the market.

Cost Expectations And Estimates

Houston pricing for concrete parking lot repair is refreshingly quantifiable for owners working with firms like Silver Spur. Most projects fall within $6,000 to $75,000, with unit slab repair averaging $8-$15 per square foot and full-depth replacement up to $25 per square foot. Common variables: total area, thickness, subgrade condition, and site logistics. Contractors who conduct a thorough survey up front provide more accurate quotes and far fewer change orders–a fact reflected in Silver Spur’s track record of delivering on-budget outcomes for Fortune 500s and local developers alike.

Why Silver Spur Stands Out

Key Differentiators Recap

Silver Spur’s competitive edge lies in single-source accountability, self-perform field crews, and deep Houston-centric material expertise. The owner’s background in large-scale industrial concrete underpins complex problem-solving capability other firms simply do not possess. Project portfolios–from ExxonMobil to Baylor College of Medicine–showcase successful outcomes under the most demanding schedules. Client testimonials confirm the firm’s ability to save both time and money without compromise on quality, and transparent safety and proposal documentation gives facility managers total confidence. Choosing Silver Spur is not a gamble–it’s the lowest risk guaranteed.

Actionable Next Steps

Stop letting marginal repairs drain your facility budget. For a comprehensive inspection, itemized estimate, and downloadable spec sheets, Request A Commercial Quote from Silver Spur now. Secure ADA compliance, protect your capital spend, and discover the transparent process difference commercial owners trust in North Houston.

Recent Comments