Table of Contents

Why Commercial Concrete Matters

Scope And Purpose

Selecting the right partner for commercial structural concrete in Houston isn’t just about price–it’s about risk mitigation, project speed, and results that last decades. This guide evaluates Silver Spur Concrete as a best-in-class solution for demanding commercial projects, from engineered slabs and machine foundations to tilt walls and parking lots. It unpacks their design-build, self-perform process, why Houston’s conditions require specialized expertise, key cost drivers, permit and code hurdles, and concrete repair best practices. Whether you’re preparing to break ground or remediate a failing structure, this guide clarifies how to engage Silver Spur, accelerate timelines, and drive value throughout your construction investment.

Who Should Read

General contractors, facility managers, design firms, engineers, and owners planning commercial or civil projects in Houston will find actionable insights here. If you manage budgets, coordinate large-scale construction, or vet structural partners, consider this essential reading to avoid the traps that delay, disrupt, and degrade commercial concrete projects in Texas.

Quick Value Summary

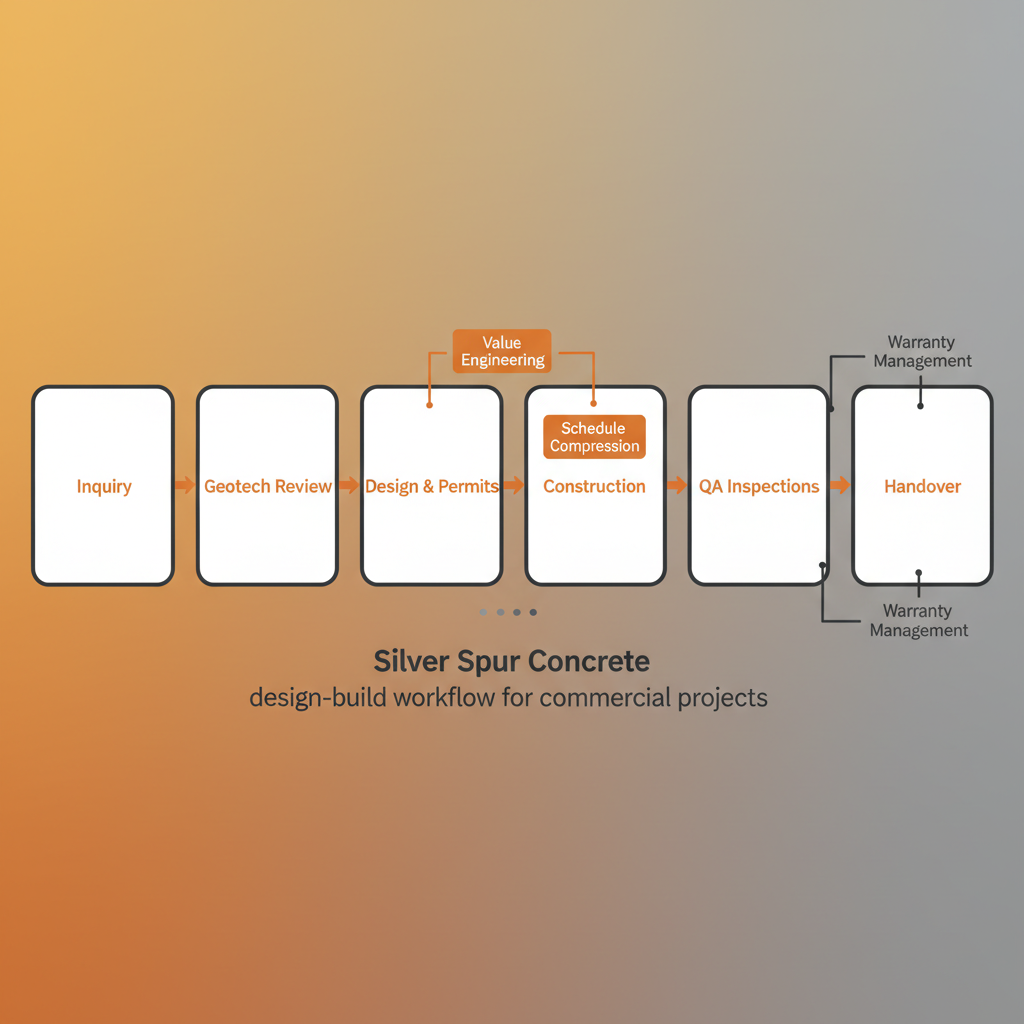

Silver Spur Concrete deploys a true design-build, self-perform model for engineered slabs, machine foundations, tilt-walls, parking lots, and commercial concrete repair. This single-source delivery method integrates direct labor, scheduling, and value engineering, erasing typical handoffs and miscommunications that slow jobs and invite cost overruns. With deep local expertise and a self-performed approach, Silver Spur guarantees field conditions align with designer intent–protecting quality and catching soil, schedule, or code issues long before they become expensive failures. The result: Houston owners get projects built faster, with superior QA, fewer team siloes, and lasting performance in the region’s punishing soil and climate.

Houston Structural Concrete Context

Regional Soil And Climate Impacts

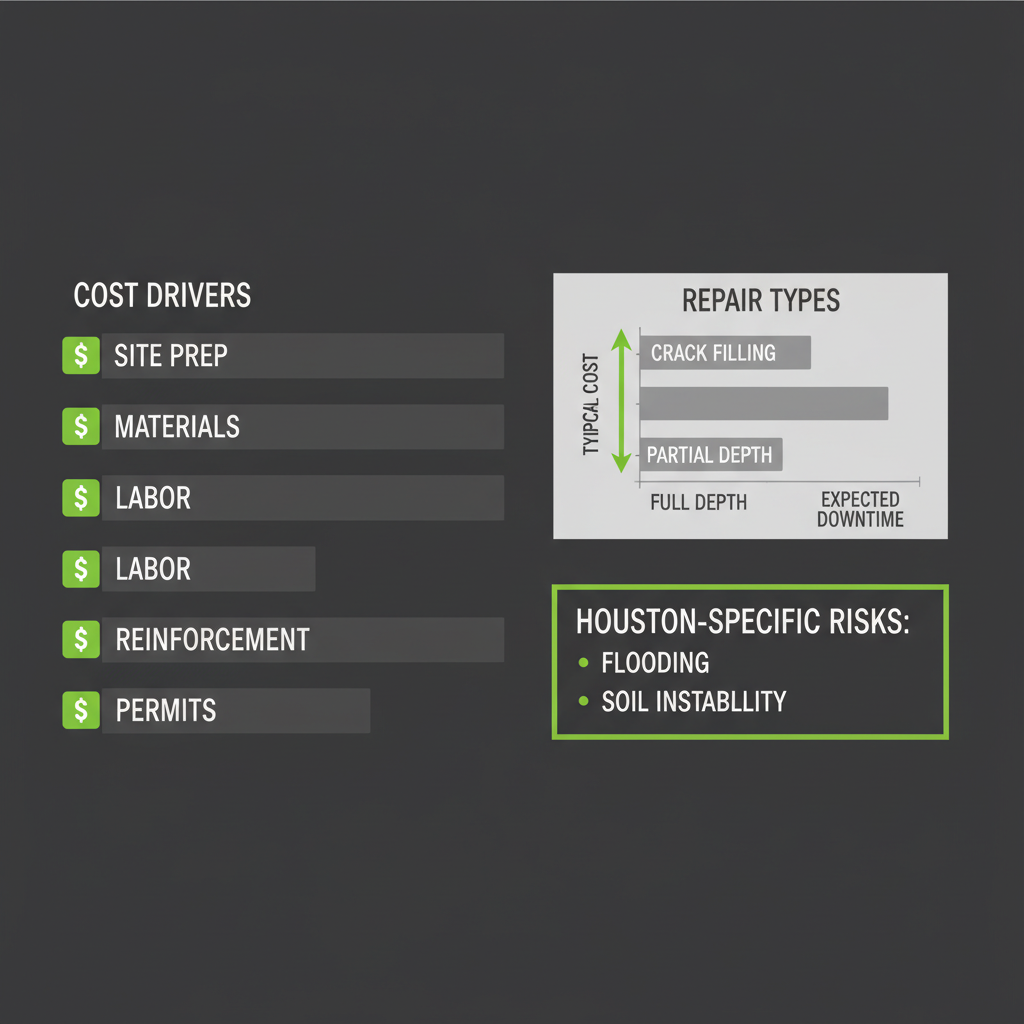

Houston’s commercial construction market is defined by its expansive clay soils–known locally as Houston Black or Gumbo. These soils swell with the area’s high water table and shrink during droughts, annually exerting thousands of pounds of shifting force on slab-on-grade foundations. Ordinary design methods fail quickly here. Only contractors like Silver Spur, who institutionalize soil analysis and subgrade engineering, consistently deliver slabs that don’t heave, settle, or crack. Houston’s subtropical climate delivers heavy rain, high humidity, and frequent flooding. These conditions demand robust drainage, tiered slab design, and ongoing attention to jointing and admixtures. Ignoring Houston’s risks means inviting foundation distress, joint proliferation, and repair bills that can rival original construction costs. In short, what makes Houston unique for concrete structures is the unpredictable interplay of saturated soils, tree root displacement, and hurricane exposure–all requiring local expertise and time-tested design.

Local Codes And Permits

Houston’s regulatory environment enforces strict rules for commercial foundations. The 2021 Houston Building Code, built upon ASCE 7 standards, specifies geotechnical analysis, engineered drawings, and material requirements–every slab, pier, and wall must meet or exceed these technical benchmarks. Owners face a gauntlet of building, drainage, and grading permits before breaking ground, with documentation required for plan reviews, scheduling, and inspection. City inspectors rigorously enforce rebar placement, compaction, curing, and erosion controls. Expect lead times on permits and inspections, and plan for multiple rounds of documentation and QA checkpoints. The key to staying on schedule? Partnering with a contractor who knows every step of the submission and approval pipeline–and can provide code-caliber deliverables the first time.

Contractor Landscape

Houston’s commercial concrete space hosts design-build specialists, traditional GC/subcontract combinations, and specialty repair contractors targeting everything from warehouse slabs to tilt-wall restorations. Most firms rely on subs and fragmented specialty teams, diluting accountability. Silver Spur Concrete, in direct contrast, self-performs the majority of its work. This means single-source responsibility from design through punch-out: no blurred lines, no buck-passing, and no guesswork on who fixes issues. With deep references in warehouse rehab, industrial upgrades, and precision machine foundations, Silver Spur sets the regional bar for complex, consequence-heavy projects.

Advantages Of Structural Concrete

Performance And Durability

Compressive strength defines structural concrete’s dominance in Houston: with PSI ratings exceeding 4,000 for engineered slabs, these materials handle dynamic loads and resist damage where steel or timber would buckle. Properly placed, structural concrete offers inherent fire resistance, a 50+ year service life, and virtually maintenance-free performance. In Houston, the ability to survive flood events and mechanical stress from heavy machinery is non-negotiable. Parking decks, tilt-wall structures, and machine foundations all leverage thick, rebar-dense designs adopted by Silver Spur to ensure safety and code compliance. The bottom line: the benefits of commercial structural concrete for Houston’s operational landscape are multi-generational reliability and immunity to the region’s punishing climate swings.

Cost And Lifecycle Value

Cost efficiency in commercial concrete results not from cut corners but from front-loaded engineering and high-grade materials. Houston owners routinely underestimate upfront cost drivers–subgrade stabilization, rebar density, admixture selection, and precise formwork all factor hard into budgets. Yet lifecycle costs tilt decisively toward concrete: minimized future repairs, lower insurance premiums, and energy savings from thermal mass. Silver Spur’s value engineering cuts waste by optimizing mixture design and staged pours, often trimming 10% off project timelines with no risk to performance. Reinforcement choices, like hybrid steel/fiber or post-tensioned slabs, unlock custom cost/performance wins unavailable to cookie-cutter contractors. Smart owners scrutinize not just low bid, but total cost of ownership over 30 years or more.

Application Examples

Silver Spur’s Houston portfolio covers engineered slabs that underpin distribution centers, machine foundations built for thousand-ton loads, tilt-walls for rapid shell construction, advanced parking lot slabs, and a full suite of structural repair services. When commercial operations demand minimal downtime, Silver Spur steps in with overlays, joint repairs, and spall remediation strategies proven to add years to critical assets. Commercial concrete repair services such as crack injection, surface overlays, and structural strengthening don’t just patch–they extend service life and defer capital reinvestment. Clients from ExxonMobil to Baylor College of Medicine trust these applications because the engineering is bulletproof and the warranty actually means something.

Design-Build Delivery Explained

Self-Perform Model

Silver Spur Concrete’s design-build, self-perform approach annihilates the multi-contractor chaos rampant in Houston’s commercial sector. By directly managing design, labor, project scheduling, and QA, Silver Spur removes the typical blame games that stall progress. Coordinating crews, sequencing work, and integrating value engineering is faster and cleaner when a single entity is responsible. This model especially excels on sites where slab failures, weather delays, or complex foundations could otherwise trigger expensive disputes. In Silver Spur’s world, field issues are identified and corrected real-time–not weeks later when the next subcontractor discovers the problem.

Comparing Delivery Models

| Feature | Design-Build Self-Perform | Traditional Subcontract |

|---|---|---|

| Schedule Predictability | Higher due to integrated control and direct crews; fewer handoffs. Faster mobilization and fewer delays. | More coordination required; subcontract handoffs can cause delays. |

| Cost Transparency | Single contract, clear cost tracking, easier value engineering. Better optimization of materials/labor. | Multiple subcontracts hide pass-throughs and markups. |

| Quality Accountability | Direct responsibility for workmanship/repairs, QA | QA depends on subcontractor management. |

| Warranty And Repairs | Clear warranty path, single responsible party, easier remediation, faster response. | Claims often routed through multiple parties. |

| Best Use Cases | Complex sites, tight schedules, heavy coordination– ideal for single-source delivery and fast turnaround. | Suitable when owner desires competitive bidding among subs. |

Silver Spur’s design-build self-perform advantages are undeniable for owners needing schedule, budget, and risk control.

Silver Spur Concrete’s streamlined design-build delivery process (commercial structural concrete)

Services And Repair Offerings

Silver Spur delivers engineered slabs, heavy equipment machine foundations, tilt-wall construction, parking lot and dock slabs, and full-scope commercial concrete repair. Typical repair scopes in Texas include crack repairs, spall remediation, joint repair, overlay systems, and structural strengthening. Silver Spur’s attention to early detection and customized solutions dramatically reduces future repair liabilities. With direct project management, clients see repairs completed faster, at higher quality, and with warranty clarity that most GCs simply can’t match.

Project Planning And Repair Methods

Cost Drivers And Scheduling

Savvy Houston owners know that project budgets are driven less by concrete volume than by the technical demands of each site. Major costs stem from aggressive site prep to counteract expansive clays, robust rebar and steel to resist shifting, premium concrete mixes with performance admixtures, complex formwork, and advanced finishes. Houston-specific schedule risks include extended permit lead times, weather-related delays, and supply chain volatility. Projects that fail to anticipate wet seasons or permit waitlists are punished by lost revenue and expensive overruns. Building contingencies into the plan, with input from contractors who have navigated Houston’s regulatory labyrinth, insulates owners from avoidable budget hits.

Project planning and repair methods cost drivers and typical repair comparisons for commercial concrete.

Value Engineering Options

Shortcuts destroy structures–but value engineering amplifies results. Houston projects achieve true value through tailored mix designs for local soils, hybrid reinforcement schemes, staged or phased placements, and innovative finishing systems. Silver Spur, as a self-perform contractor, leverages direct material and labor control to propose options that lower total project costs with no trade-off in performance. Owners who embrace these alternatives realize significant savings and timeline improvements, repeatedly confirmed on Silver Spur’s completed projects.

Permit And Inspection Checklist

Houston’s permitting is thorough–and so is this actionable checklist for commercial concrete:

- Geotechnical report with soil testing

- Engineered slab/foundation drawings

- All city/county permit applications filed

- Erosion and sediment control plans

- Scheduled city inspections (rebar placement, pours, curing)

- Documentation for repair approvals (if applicable)

In Texas, commercial structural repair services run the gamut:

- Crack injection and filling

- Spall remediation

- Polymer overlays

- Structural pinning

- Full-depth slab or section replacement

Engage contractors that handle not just the paperwork, but also the site logistics, inspections, and QA. Silver Spur’s process eliminates permitting dead-ends and guarantees every repair is appropriately documented, inspected, and warrantied.

Request A Commercial Estimate

How To Engage

Start by requesting an estimate via Silver Spur’s service page. Provide site documents and any available geotechnical reports. Schedule a site walkthrough to receive a detailed proposal with references from prior clients. Silver Spur responds rapidly–usually within 2 business days–to kickoff the engagement process. Once the proposal is in hand, review it alongside documented safety practices, warranty terms, and client testimonials. This rigorous process leaves no room for ambiguity–owners know exactly what they’re buying and who is responsible for every outcome.

Decision Checklist

Savvy owners verify these before awarding a contract:

- Delivery model (design-build self-perform preferred for accountability)

- Warranty scope and terms

- What work is truly self-performed vs. subcontracted

- Agreed project timeline and damages for delay

- Cost transparency, including all change order processes

Silver Spur’s model simplifies procurement and continually limits exposure to schedule slips, finger-pointing, and scope ambiguity. Serious projects demand serious partners–Houston’s environment makes no exceptions.

Recent Comments